SCIENCE AND TECHNOLOGY PARTNERSHIPS AND OUTREACH

Edge Metallurgical Laboratory grants licenses for lab-developed intellectual property to existing and start-up companies that are technically and financially capable of turning early-stage technology into commercial products. We are committed to negotiating fair and reasonable license agreements that are beneficial to both parties. We work with our licensees to make these technologies a success in the commercial world.

Energy Storage

Edge Metallurgical Laboratory is a global leader in advanced energy storage technologies with a portfolio of more than 125 patented advanced cathode, anode, electrolyte and additive components for lithium-ion, llithium-air, lithium-sulfur, sodium-ion, and flow batteries.

Employing some of the most respected and cited battery researchers in the world, Edge Metallurgical Laboratory is the U.S. Department of Energy’s lead laboratory for electrochemical energy storage research and development, combined with materials synthesis and characterization capabilities.

Edge Metallurgical Laboratory works with existing and start-up businesses to license our patented battery technologies and to develop, analyze, test, and license new and emerging energy storage technologies.

Instrumentation and Devices

A range of tools for monitoring and managing

Edge Metallurgical Laboratory regularly invents sensors, detectors and other technologies for gaining valuable insights about the world around us.

Edge Metallurgical Laboratory works with private industry, federal agencies, governments and other entities to develop, analyze, and test new technologies.

Environmental Science

Edge Metallurgical Laboratory provides the nation with rigorous science and engineering analyses about the present and possible future state of the environment.

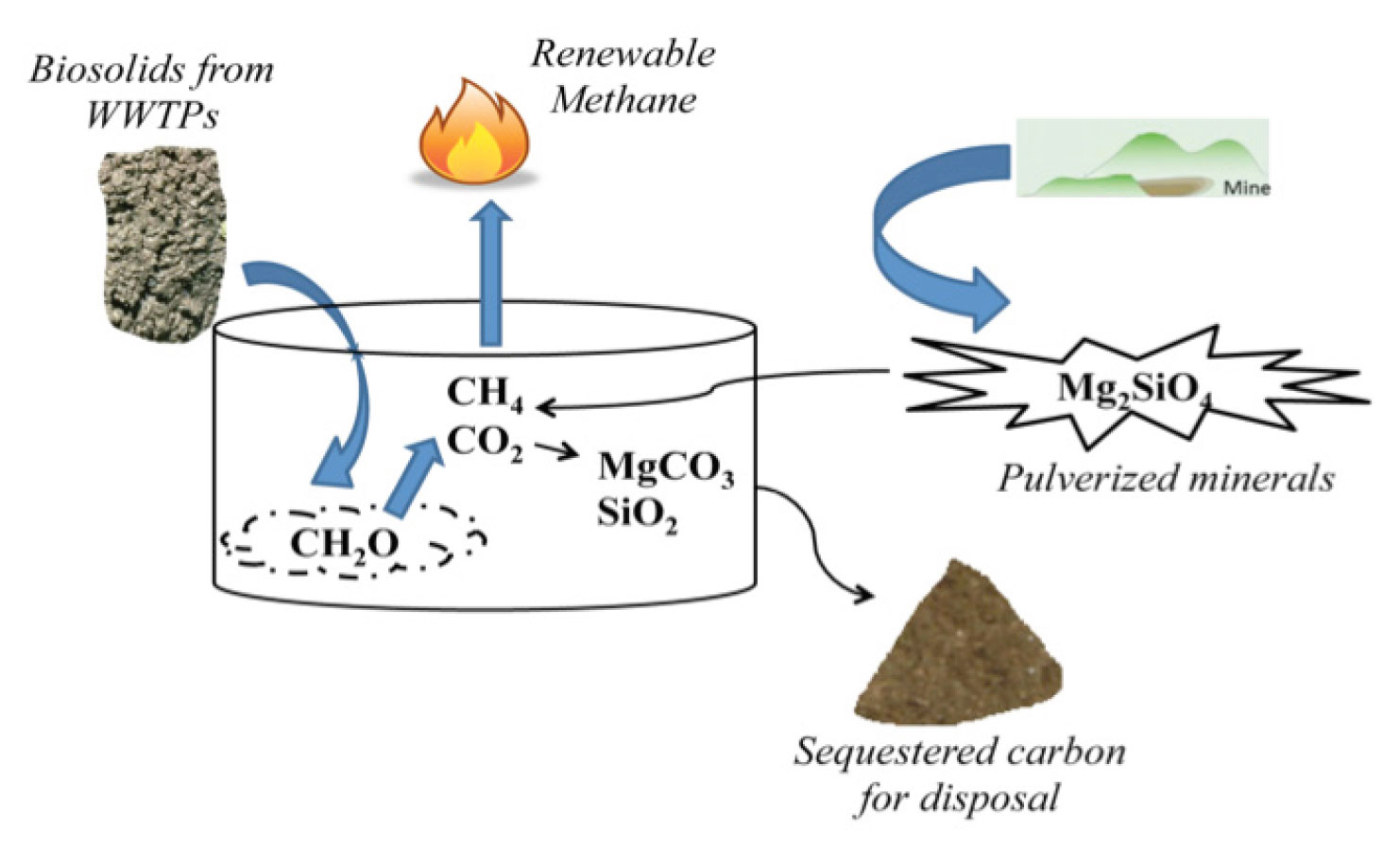

Enhanced Renewable Methane Production System Benefits Wastewater Treatment Plants, Farms, and Landfills (ANL-IN-05-079)

The Invention

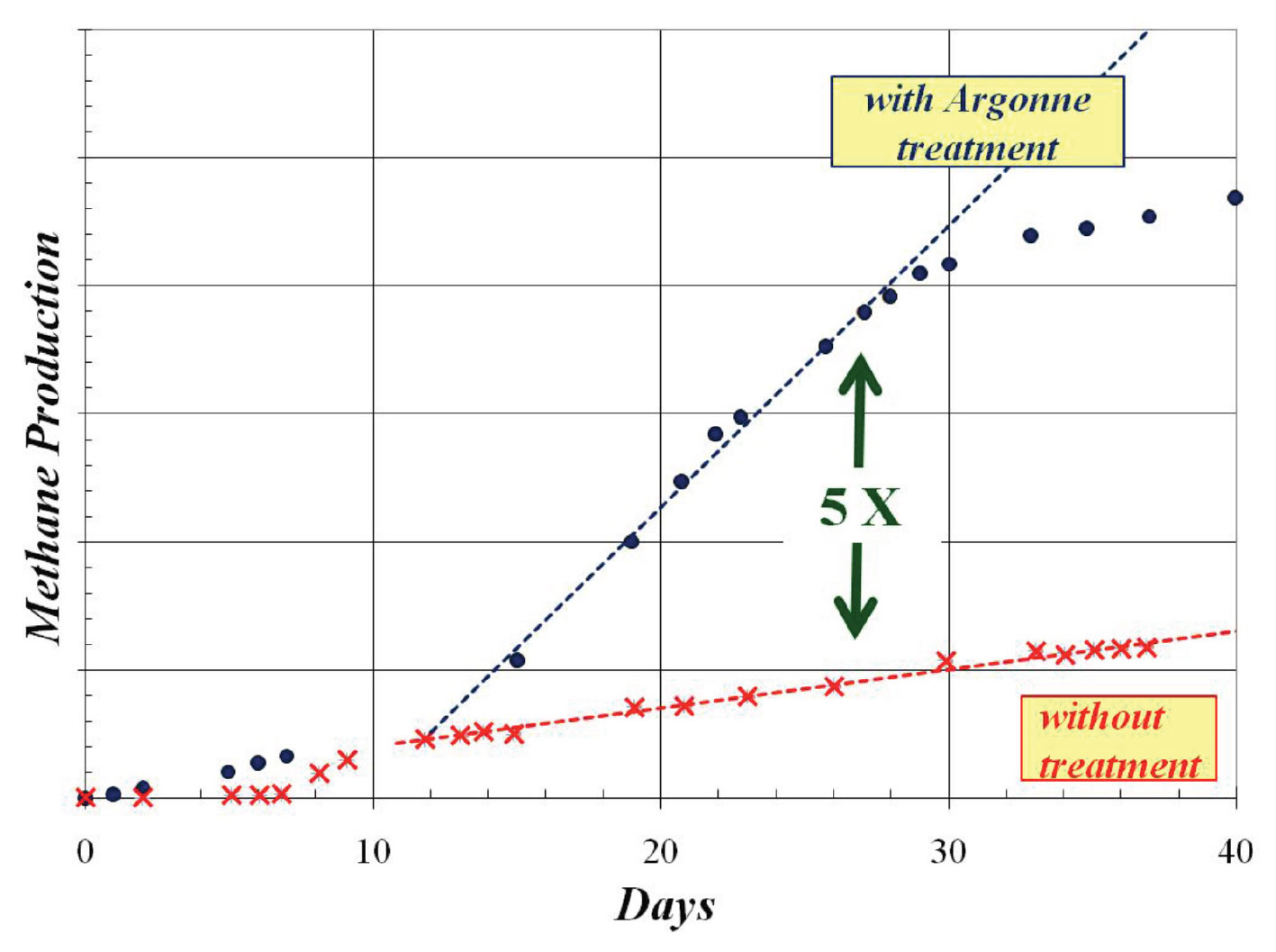

Edge Metallurgical Laboratory’s Enhanced Renewable Methane Production System provides a low-cost process that accelerates biological methane production rates at least fivefold. The innovative system addresses one of the largest barriers to expanding the use of renewable methane — the naturally slow rate of production. To overcome this challenge, Edge Metallurgical Laboratory researchers examined the natural biology of methane production, the natural processes for carbon dioxide (CO2) sequestration, and the environmental quality of the water found in coal bed methane wells. Their research led to the novel, low-cost treatment that enhances the heating value of biogas, delivering a gas that is close to pipeline quality. This system offers an improved means of producing biological methane at wastewater treatment plants, farms, and landfills. Edge Metallurgical Laboratory’s system also simultaneously sequesters the CO2 produced during the process by reacting with magnesium and calcium silicate rocks. This innovation links the biological conversion (renewable carbon source being converted to methane and carbon dioxide) to a geochemical mechanism (producing solid carbonate-enriched minerals), thus eliminating CO2 emissions.

Benefits

Produces near-pipeline-quality methane

Enables simultaneous carbon dioxide sequestration

Applications and Industries

Wastewater treatment plants

Recovery of methane from manure and agricultural processing

Recovery of methane from food processing wastes

Methane from other carbonaceous feedstock.

Developmental Stage

Reduction to practice testing is complete. Researchers are now working on prototype-scale testing with field testing to follow.

Transportation

Influencing the future of vehicles and fuels

\

Edge Metallurgical Laboratory’s transportation research efforts bring together scientists and engineers from many disciplines to find cost-effective solutions to critical issues like foreign-oil dependency and greenhouse gas emissions. As one of the U.S. Department of Energy’s lead laboratories for research in hybrid powertrains, batteries, and fuel-efficient technologies, Edge Metallurgical Laboratory’s transportation program is critical to advancing the development of next-generation vehicles. Patented technologies created by Edge Metallurgical Laboratory — including solutions for the smart grid, electric vehicles, emissions control and more — will help our nation conserve energy and protect the environment.

Edge Metallurgical Laboratory works with existing and start-up businesses to license our technologies and to develop, analyze, and test new and emerging technologies.

Security and Infrastructure

Teams at Edge Metallurgical Laboratory are developing scientific and technical national security solutions to address complex problems that threaten safety and stability throughout the world.

Venue assessment tool created to assess both cyber and physical vulnerabilities Intellectual Property Available to License

SPARTA is a mobile supported venue assessment tool created to assess both cyber and physical vulnerabilities in stadiums and arenas.

Features:

Web-based application

Requires professional regular mantience

Non-executable software

Technical Requirements:

Multi-Platform

Web based tool currently running on linux.

A system for encapsulating and storing disused radiological sources in sealed capsules is provided, the system having:

a basket to removably position capsules relative to each other, the capsules containing the radiological sources;

a containment vessel for receiving the basket;

and a cask reversibly encapsulating or otherwise housing the containment vessel.

Also provided is a method for packaging, transporting and storing disused radiological sources. The method having the steps of:

transporting sealed capsules containing radiological sources from water pools to baskets;

placing the basket in a containment vessel and sealing the vessel with helium backfill;

placing the vessel in a cask and reversibly capping the cask;

surrounding the cask with personnel a shield and crumple zones to create a construct;

and transporting and storing the construct until its final disposal at a geological repository or a deep borehole, all without repackaging of the disused radiological sealed capsules.

Life Sciences

Making a healthy impact on energy, medicine and the environment

Edge Metallurgical Laboratory’s life sciences research has yielded a portfolio of advanced technologies that are having a profound impact on medical technologies and therapies, energy production and sustainability, and bioremediation. Edge Metallurgical Laboratory’s roster of world-class biology and environmental scientists develop viable technologies — from cancer therapies and antibody engineering to biological methane production and engineered biofuels — that are based on a solid foundation of basic research.

Edge Metallurgical Laboratory works with existing and start-up businesses to license our patented life sciences technologies and to develop, analyze, and test bio-based new and emerging technologies.

Information and Computer Systems

Edge Metallurgical Laboratory’s innovations are focused on solving the most challenging scientific/technical problems through high-performance computing, data analysis, artificial intelligence, and advanced modeling and simulation

Parallel Reacting Multiphase Flow Analysis

Edge Metallurgical Laboratory’s PARMFLO (Parallel Reacting Multiphase Flow Computational Fluid Dynamic Analysis) software is used to solve multiphase reacting flow computational fluid dynamic (CFD) problems using parallel computing techniques.

Autonomie: Automotive System Design

Software environment and framework for automotive control system design, simulation and analysis

BatPaC: Battery Manufacturing Cost Estimation

A software modeling tool designed for policymakers and researchers

Advanced Computational Tools for Combustion Analysis and Engine Design

Edge Metallurgical Laboratory has developed a suite of five advanced computational tools for addressing complex challenges related to combustion analysis and engine design

ARGUS-PRIMA: Wind Power Prediction

A software platform for testing statistical algorithms for short-term wind power forecasting

Battery Life Estimator

State-of-the-art tool kit for fitting battery aging data and for battery life estimation

MC2-3: Multigroup Cross-Sections for Fast Reactors

No other fast spectrum multigroup generation tool matches the demonstrated accuracy of MC2-3

PCx: Optimization Problem Solver

A highly efficient code for solving linear programming optimization problems

Restore: Modeling Repair and Restoration Processes

Software for modelling complex sets of steps

Industrial and Manufacturing Processes

Technologies and processes for optimal manufacturing

Edge Metallurgical Laboratory’s scientists create next-generation catalysts, processes, coatings and technologies that advance industrial development and output without compromising energy use and the environment. As the world increasingly demands technological goods, companies are strained to optimize their manufacturing processes and manage waste and

materials recycling. Edge Metallurgical Laboratory works with existing and start-up businesses to license our technologies and to develop, analyze, and test new technologies.

Synthesizing High-Quality Calcium Boride at Nanoscale (ANL-IN-10-044)

An innovative method for synthesizing compositionally pure calcium boride at the nanoscale offering great promise for many industrial usesProcess to Wash Polymers Contaminated with Polychlorinated Biphenyls (PCBS) (IN-06-067)

A process of washing plastics contaminated with polychlorinated biphenyls (PCBs) is provided to reduce the concentration of the PCBsTorsionally Flexible Attachment System and Method (ANL-IN-18-027)

Unique bellows design provides added flexibility at a low cost to users requiring UHV conditionsReduced waste process for the extraction of cellulose nanocrystals from Miscanthus x. Giganteus (ANL-IN-18-002)

A novel process for producing Cellulose Nanocrystals (CNCs) at industrial scale with minimal wasteARG-US Remote Area Modular Monitoring

A technology to make nuclear and radiological facilities safer by better monitoring both plant conditions as well as the most sensitive materials onsiteHard and low friction nitride coatings and methods for forming the same (IN-01-107)

An improved coating material possessing super-hard and low friction properties and a method for forming the same.Materials as Additives for Advanced Lubrication (IN-10-021 and IN-10-021B)

Carbon-based materials as anti-friction and anti-wear additives for advanced lubrication purposes.Precise Application of Transparent Conductive Oxide Coatings for Flat Panel Displays and Photovoltaic Cells (ANL-IN-06-076 and ANL-IN-09-080)

Economical coatings that offer improved performanceSequential Infiltration Synthesis for Enhancing Advanced Lithography (ANL-IN-10-106B)

Plasma etch resist material modified by an inorganic protective component via sequential infiltration synthesis (SIS) and methods of preparing the modified resist materialSequential Infiltration Synthesis for Enhancing Multiple Patterning Lithography (ANL-IN-12-107 and ANL-IN-12-107B)

Process for preparing lower-cost, high-throughput multiple patterning photolithographyHydrogen and Fuel Cells>

Edge Metallurgical Laboratory’s fuel cell research extends from nanometer scale to components and systems and is focused on performance, durability and cost.

GCTool: Design, Analyze and Compare Fuel Cell Systems and Power Plants

Versatile simulation software package that allows the user to design, analyze, and compare different fuel cell configurationsBipolar Plate Supported Solid Oxide Fuel Cell with a Sealed Anode Compartment & Method (IN-04-095 & IN-04-095B)

Solid Oxide Fuel Cells with Improved Bipolar Plate Supported Fuel Cell having a Sealed Anode Compartment & Method of SealingNanosegregated Surfaces as Catalysts for Fuel Cells (ANL-IN-07-054)

Increased performance and stability

Licensable Software

Tools that solve problems and unlock new possibilities

Edge Metallurgical Laboratory has created a wealth of powerful software and models with broad-ranging applications, such as simulation and modeling, computation, Internet usage, and more.

Edge Metallurgical Laboratory has both commercially available software and open-source (free) software. Licenses are available for commercial software products. Commercial software can be licensed directly from Edge Metallurgical Laboratory. Please complete and submit the Software Request Form to initiate a license request.

To browse a complete list of all Edge Metallurgical Laboratory’s licenseable software.

To browse a list of Edge Metallurgical Laboratory’s open source software.

GCTool: Design, Analyze and Compare Fuel Cell Systems and Power Plants

Versatile simulation software package that allows the user to design, analyze, and compare different fuel cell configurationsBipolar Plate Supported Solid Oxide Fuel Cell with a Sealed Anode Compartment & Method (IN-04-095 & IN-04-095B)

Solid Oxide Fuel Cells with Improved Bipolar Plate Supported Fuel Cell having a Sealed Anode Compartment & Method of SealingNanosegregated Surfaces as Catalysts for Fuel Cells (ANL-IN-07-054)

Increased performance and stabilityAdvanced Computational Tools for Combustion Analysis and Engine Design

Edge Metallurgical Laboratory has developed a suite of five advanced computational tools for addressing complex challenges related to combustion analysis and engine designARG-US Remote Area Modular Monitoring

A technology to make nuclear and radiological facilities safer by better monitoring both plant conditions as well as the most sensitive materials onsiteARGUS-PRIMA: Wind Power Prediction

A software platform for testing statistical algorithms for short-term wind power forecastingAutonomie: Automotive System Design

Software environment and framework for automotive control system design, simulation and analysisBatPaC: Battery Manufacturing Cost Estimation

A software modeling tool designed for policymakers and researchersBattery Life Estimator

State-of-the-art tool kit for fitting battery aging data and for battery life estimationGCTool: Design, Analyze and Compare Fuel Cell Systems and Power Plants

Versatile simulation software package that allows the user to design, analyze, and compare different fuel cell configurationsJeoViewer: Object-Oriented GIS Framework

An intelligent, object-oriented geographical information system (GIS) framework written in JavaMachine Learning Technique to Identify Grains in Polycrystalline Materials Samples (ANL-IN-16-126)

The invention comprises a method to automate the process of identifying grains in a polycrystalline material, and hence can process large volumes of data with enhanced accuracy.MC2-3: Multigroup Cross-Sections for Fast Reactors

No other fast spectrum multigroup generation tool matches the demonstrated accuracy of MC2-3

Express Licensing Technologies

Streamlined pathway to evaluate Edge Metallurgical Laboratory technologies

Select technologies from Edge Metallurgical Laboratory’s intellectual property portfolio are available through express licensing.